About the 8235-360

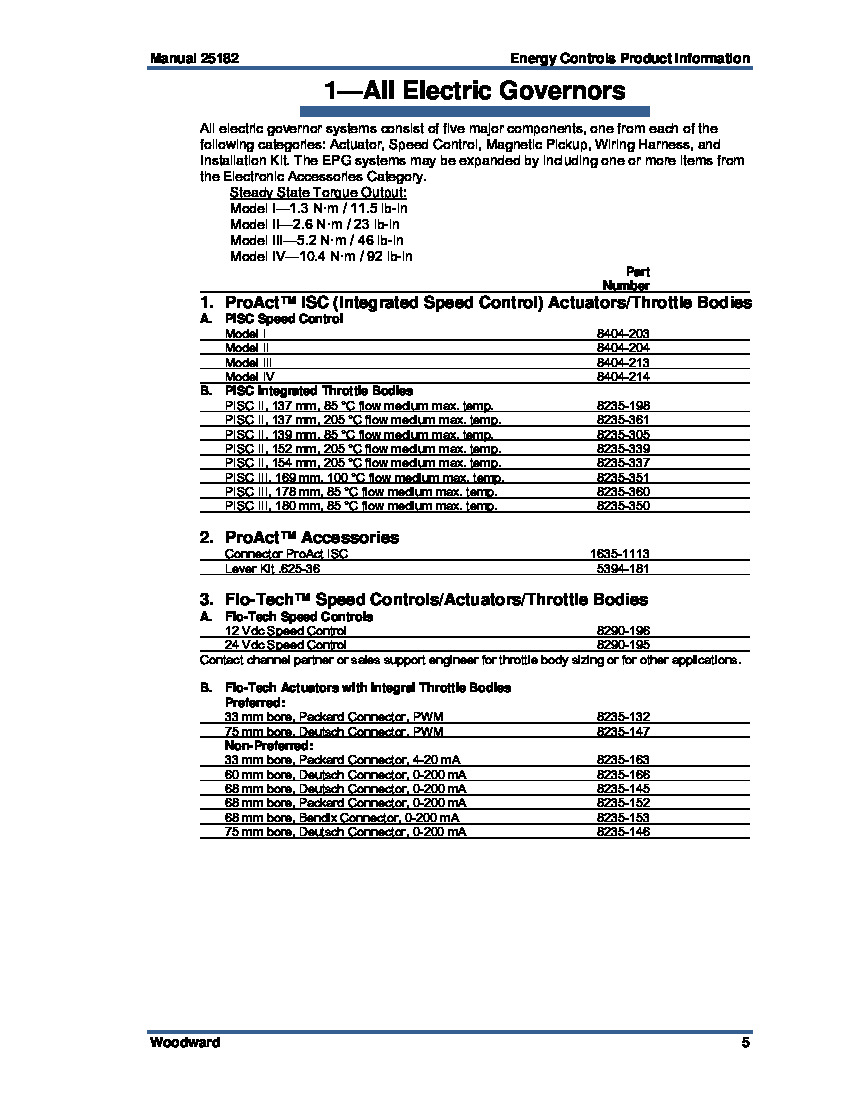

Woodward model 8235-360 is one of the models in the ProAct and ProAct Plus Series of Actuators and Drivers. This model is used with a PISC III actuator. When performing during normal operation the actuator will operate in the range of eighteen to thirty-two VDC, and when starting or transient the model will be 8-40 VDC for at least a minute. When being mounted the attaching hardware as well as the brackets needed are required to hold the weight of the throttle assembly and must withstand the vibration related to the engine mounting.

When operating the 8235-360 model with the chosen governor and a troubleshooting error occurs any issues regarding the governor can be rectified by being cautious and repeating the calibration procedure. If needed, attempt to isolate the governor from the engine to assess that problems are occurring within the governor rather than the load on the engine or the engine itself. Any faults regarding the governor usually occur after installation.

If any adjustments of the 8235-360 or the PISC III actuator are required adjustments are made through a ProAct ISC (Integrated Speed Control) Service Tool. This tool runs on a personal computer and will communicate with the PISC through a serial connection, when the control is not being used the tool will be disconnected.

While the PISC III model can be used to initiate an engine shutdown please note that it should not be the primary shutdown mechanism. All information regarding the system operation, installation, troubleshooting, etc. can be found in both the Woodward 26246 and 26265 manuals. The 26265 manual contains information regarding the 8235-360 and the 26246 manual contains information regarding the PISC actuators.