Do you know the advantages of overstock/refurbished industrial equipment?

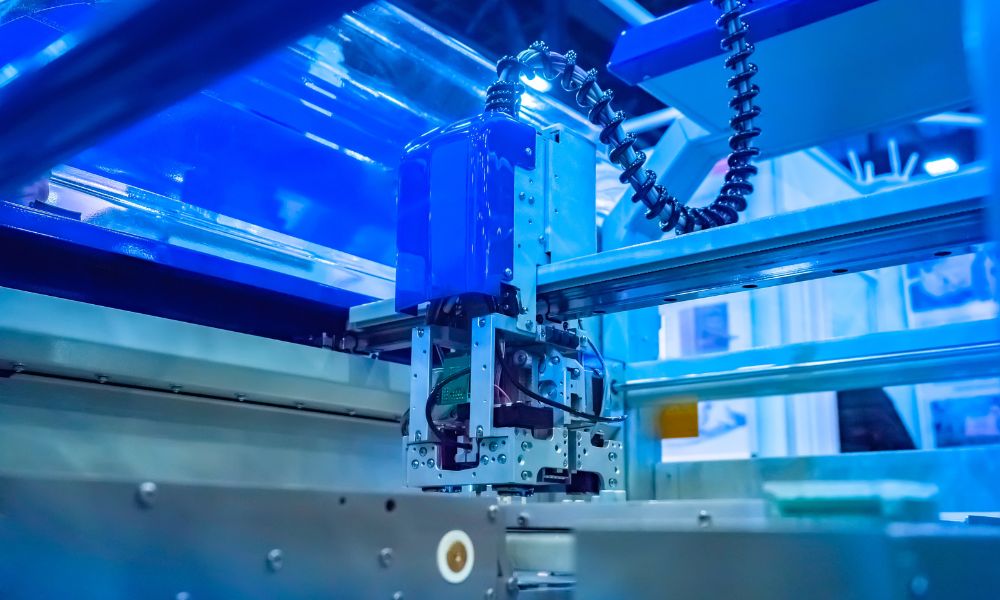

The choices when you buy industrial automation equipment are varied. Do you buy new? Overstock? Refurbished? Do you consider repairing your current part?

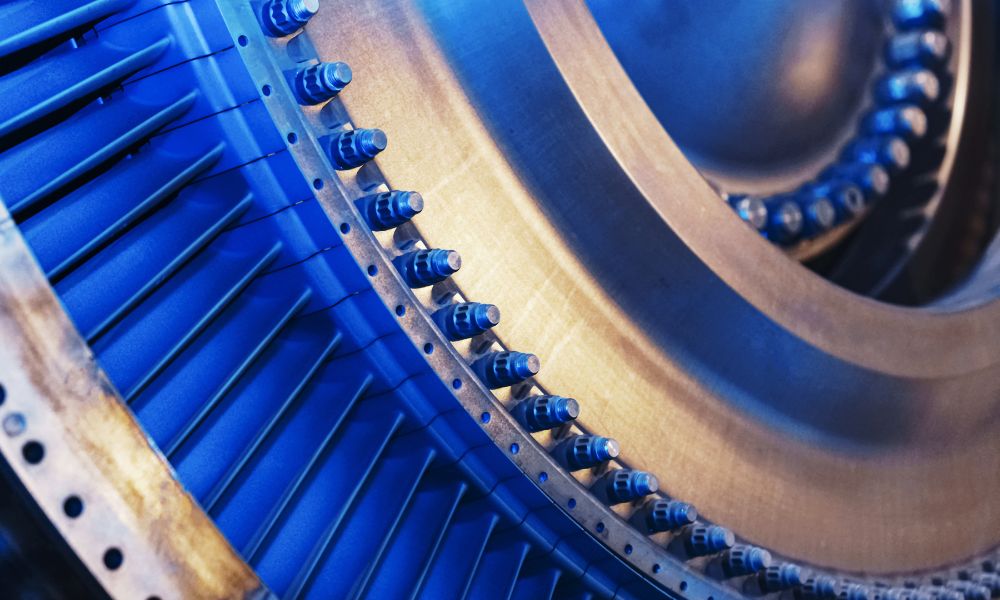

The age of your factory automation systems and the availability of parts will drive some of these decisions. OEMs give limited options for older legacy systems. And the longer a system remains in use after legacy status, the more challenging it becomes to source quality replacement parts.

Here at AX Control, we stock a wide range of professionally refurbished, repaired, and reconditioned automation parts from companies like GE, Eurotherm, and Reliance Electric, just to name a few. We inspect, clean, test, and bring every piece of legacy equipment in our inventory back to proper working order. Only then is it placed into our online inventory.

Continue reading “Overstock/Refurbished Industrial Equipment: Advantages”

You must be logged in to post a comment.