Transformers are an essential tool for voltage manipulation in all distribution systems. In addition to transformers being among the most critical components in distribution, they are also the most expensive. This makes repair and replacement an incredibly costly endeavor—and one that needs to be undertaken quickly.

Fortunately, transformers are enclosed in static devices, and wet transformers are drenched in oil. Typically, these safety measures make faults quite limited. However, even the best-laid-out plans can go awry, which is why it’s crucial to employ means of transformer protection. Read on to discover the common types of transformer protection systems.

What Is Transformer Protection?

Rare as they may be, internal faults in transformers can progress to cause significant damage to the device. Transformer protection is a catch-all term that can apply to any number of protective enhancements and additions you can add to a transformer.

These systems work to find internal faults in a transformer with varying degrees of sensitivity, and some can additionally provide back-up protection in the case of a fault. These systems can sense varying factors, including current, voltage, frequency, oil pressure, and temperature.

However, not all transformers will include the same protection systems. Many facilities need to take into account their budget and determine the most important protection systems to include in a given machine. In many instances, there are certain varieties of faults that are more likely to occur than others; these should be given priority when designing a transformer’s protection systems.

When choosing protective systems and determining which are worth including, you cannot forget about the possibility that transformer failure could result in damage to nearby pieces of equipment and infrastructure.

Finally, it is essential to consider the cost of the protective device in comparison to the cost of replacing or repairing the transformer. For many budgets, there comes a time when it costs more to install more protection than it would to repair a transformer. All these factors must be considered when choosing which protective systems to use.

Why Is Transformer Protection Important?

We’ve already touched on some of the financial incentives you may have for keeping your technicians in the know about transformer faults, but there are also other considerations. For instance, a fault can affect your bottom line in more ways than replacement costs, as downtime is also an expensive proposition.

Protection is an essential feature used to keep the time of disconnection to a minimum and to reduce the possibility of catastrophic failure. The longer you have a transformer that operates in sub-optimal conditions, the more likely you are to compromise the life span of the transformer.

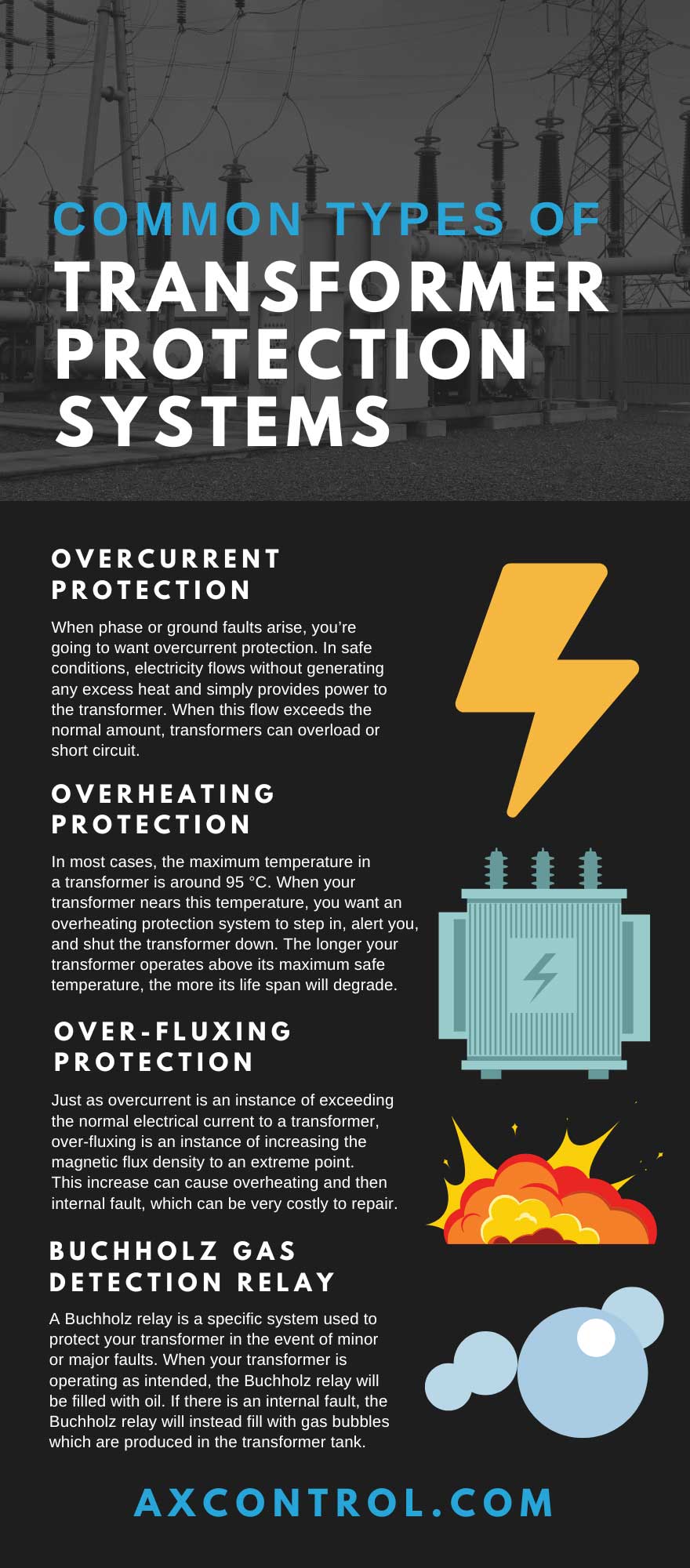

Overcurrent Protection

When phase or ground faults arise, you’re going to want overcurrent protection. In safe conditions, electricity flows without generating any excess heat and simply provides power to the transformer. When this flow exceeds the normal amount, transformers can overload or short circuit.

The simplest means of providing overcurrent protection is with fusible links, fuses, and circuit breakers. All these pieces of hardware can limit or even disable the flow of an electrical current.

Keep in mind that this hardware will not correct the overcurrent problem. Instead, they will stop the flow of electricity by tripping circuit breakers and blowing the fusible links.

Overheating Protection

As you may imagine, one of the biggest problems that protection systems need to be aware of is overheating. Whether the overheating comes about due to a short circuit or an overload, either possibility can be devastating.

In most cases, the maximum temperature in a transformer is around 95 °C. When your transformer nears this temperature, you want an overheating protection system to step in, alert you, and shut the transformer down. The longer your transformer operates above its maximum safe temperature, the more its life span will degrade.

Operating above this maximum temperature can also degrade wire insulation, which can cause other problems down the road. In many transformers, fiber-optic cables are used to measure the temperature in the transformer core. It’s at the center of the transformer where you’ll encounter the highest temperatures, which is why fiber-optic cables need to access that area.

Over-Fluxing Protection

Just as overcurrent is an instance of exceeding the normal electrical current to a transformer, over-fluxing is an instance of increasing the magnetic flux density to an extreme point. This increase can cause overheating and then internal fault, which can be very costly to repair.

Over-fluxing protection works similarly to overcurrent protection. When the flux density ratio increases to a dangerous level, the system will send a signal to the circuit breaker, telling it to trip. This will shut down your transformer and prevent any further damage.

Buchholz Gas Detection Relay

A Buchholz relay is a specific system used to protect your transformer in the event of minor or major faults. When your transformer is operating as intended, the Buchholz relay will be filled with oil. If there is an internal fault, the Buchholz relay will instead fill with gas bubbles which are produced in the transformer tank.

These gas bubbles accumulate until they trigger an alarm element in the Buchholz relay. If the problem is not addressed in time, the Buchholz relay will secondarily trigger a trip element. This occurs in the case of rapid oil loss due to serious faults. Simply put, a Buchholz gas-detection relay gives you an opportunity to fix a problem and then provides a failsafe in the case you cannot.

Whether for transformers or other industrial systems in need of motor control, you can rely on AX Control Inc. to provide you with the very best in motor management systems. When you need precise and total monitoring for motors in your facility, you can’t go wrong with the products we have in stock now.

Now that you know these common types of transformer protection systems, make sure your facility is equipped with all the protective systems it can be. As the saying goes, an ounce of prevention is worth a pound of cure. Don’t forget to be proactive, as it can save you a lot of money in the long run. If you need help finding protection systems for your facility, don’t hesitate to reach out to our team. We’re happy to help!

You must be logged in to post a comment.