Motion control systems have a long history—much longer than you may expect! Perhaps the earliest case of a motion control system dates back to the 1780s, a system called the flyball governor. While this motion control system had nothing to do with computers, almost all modern motion control systems use computers to supervise the process. Read on to learn everything you need to know about motion control systems.

What Is a Motion Control System?

If we look back at the flyball governor, its main purpose was the same as any motion control system of today: to control energy in order to create mechanical motion. In the case of the flyball governor, it used centrifugal force to set a throttle angle and maintain engine speed on the Watt steam engine.

Today, motion control systems take that same principle and add computers into the mix to make sure everything is working optimally.

When we get a bit more technical, motion control uses linear and rotary actuators to move machinery and control the force, position, velocity, or pressure of a machine.

For a better picture of how these devices work, let’s break it down into components.

Motion Controllers

You can think of the motion controller as the brain of the system. In modern motion control systems, commands can be complicated, and motion controllers generate and calculate these commands and convey the information to the rest of the system. When the motion controller receives feedback, it can adjust its commands to do what’s best for the system.

All these processes work using algorithms like control loops, step generators, and interpolators. These calculate the required movements based on any number of set points in the machine.

Drives

When motion controllers send commands to the rest of the system, they send them in low-voltage signals to drives. The drives are an essential middleman, conveying the signals to other components in the system. Depending on your system, you may use digital, analog, linear, or switching drives, stepper or microstepper drives, or servo drives.

All these drives are unique—for example, while switching drives are highly efficient, they’re quite noisy. On the other hand, linear drives are quiet but have low efficiency.

Motors

Without the capability to convert electrical energy into mechanical energy, motion control systems couldn’t get anything done. If the motion controller is the brain, motors are the muscles—they hear commands from the controller and carry them out physically.

DC motors require both a mechanical communicator and carbon brushes to achieve torque in a system and will operate continuously as long as they have DC power. DC motors are high maintenance and among the larger motors in size.

Brushless servo motors, unlike DC motors, do not use brushes. Their rotation derives from electrical communication in the drive. These are generally smaller than DC motors and require low maintenance for the high torque they provide.

Meanwhile, stepper motors are perhaps the most precise of all—because they use multiple coils in phases, they can rotate the motor a single step at a time. This is perfect when you need tight control over speed and positioning.

Feedback Devices

In closed-loop systems, feedback devices are essential so that the motion controllers can adjust the directions they give out to the system. One of the most common types of feedback devices is an encoder, which provides the motion controller information about the direction, position, and velocity of set parts.

Applications of Motion Control

Aside from the flyball governor at work in the Watt steam engine, where else could you expect to find motion control technology?

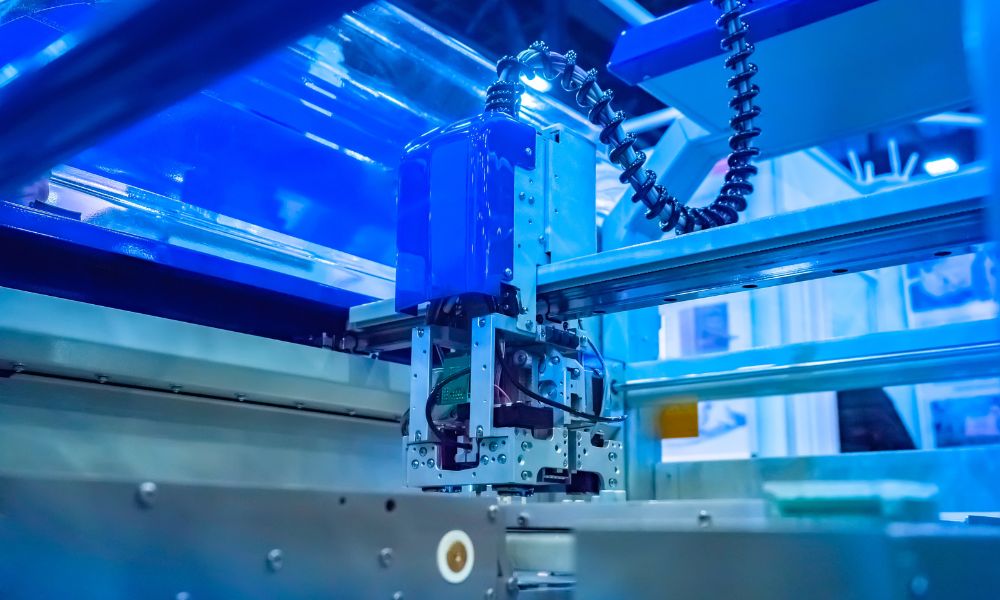

About 90 percent of the time, you’ll find motion control systems at work in industrial settings. Whether motion controllers are keeping an eye on conveyor systems or acting as the brains of advanced robotics, these devices keep factories and other industrial facilities up and running.

The field of automation is constantly growing as the world moves toward faster and faster methods of production. You may have heard Amazon is currently investing in robotics to help warehouse employees pull stock for shipping—those robots will have several motion control systems inside them to function.

In addition, you would be hard pressed to find a military base without motion control systems. From the servo motors on gun mounts to missile flight simulators, motion controllers are essential for keeping our country safe.

Choosing Motion Control Parts

It can be challenging to determine the best motion control parts for your application. There are a few things to keep in mind when the time comes to select parts for your applications.

First, make sure you know your system requirements. Systems can have widely varying applications, so define your unique conditions. Once you have, it will be much easier to find compatible components.

In addition, don’t underestimate the importance of the motion controller. When purchasing a standalone motion controller, remember that it acts as the brain of the whole system—if the brain doesn’t work, the rest of the body won’t either. Consider everything from the coordinated motion requirements to the programming language and error-handling capabilities of the motion controller. Be sure to find one that is well suited to the unique needs of your system.

On top of that, work with a vendor that knows motion control. This is a complicated field, and it helps to have someone in your corner who understands how these devices function.

Finally, don’t hesitate to consider a custom solution. If your applications are particularly complex, one of the best ways forward is with a system built specifically for you. With these factors in mind, you can rest assured knowing that your system will offer optimal performance for your needs.

Now that you have everything you need to know about motion control systems, we hope you have a greater understanding of the industrial sector and how useful this technology is. The technology in this field is always changing and developing, so stay tuned—we’ll be sure to update you about any advancements!

You must be logged in to post a comment.