About the IS200WETAH1ADC

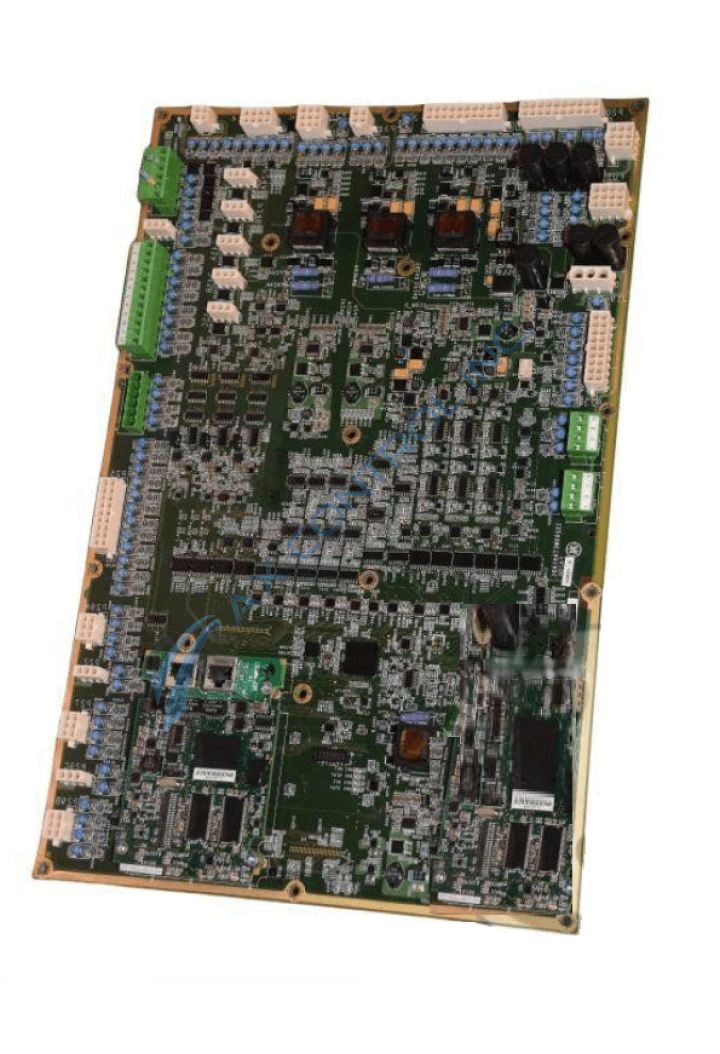

This PCB is most often used in Wind Energy applications. Many Mark VIe control systems have been used for Wind Energy; there have been more than 30,000 installations in wind turbines over the last few years. Mark VIe systems are designed for use in many applications that need distributed control systems. This includes thermal, hydro, wind, oil & gas, as well as nuclear facilities. Part of the appeal of the Mark VIe is its flexible platform (capable of setting up in a simplex, dual, or TMR configuration) that offers industry-standard Ethernet capability for I/O controllers with a connected interface that offers supervisory control, most typically using GE’s ControlST software. The IS200WETAH1ADC has many components on its surface. This includes:

- a connected auxiliary (daughter) board that attaches to its surface via a plug connector

- four transformers

- six terminal strips

- seven fuses

- 25 tp test points

- multiple jumper switches

- integrated circuits

- diodes

- relays

- inductors

- plug and jack connector

Wind Energy Top Assembly Part Number IS200WETAH1ADC

The IS200WETAH1ADC Wind Energy Top Assembly functional product number itself codes for a number of relevant IS200WETAH1ADC Wind Energy Top Assembly device qualities through its General Electric-formulated series of functional naming nuggets. One such nugget can be identified in the IS200WETAH1ADC Wind Energy Top Assembly functional product number's initial IS200 series tag that outlines this IS200WETAH1ADC Wind Energy Top Assembly product's normal Mark VI Series assembly version as well as its domestic location of GE manufacture in a typical fashion. Some of the other IS200WETAH1ADC Wind Energy Top Assembly hardware details revealed in this way include its:

- WETA functional product acronym

- Group one Mark VI Series product grouping

- Conformal PCB coating style

- Three-fold revision table