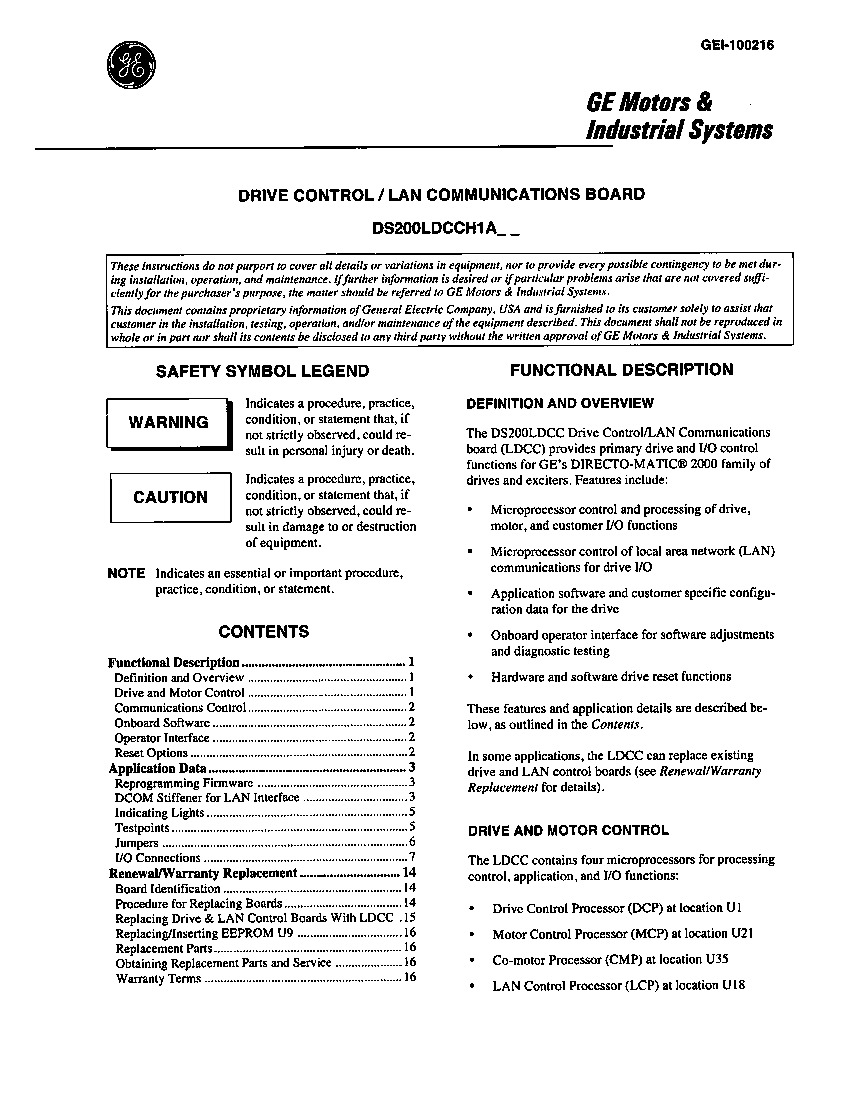

About the DS200LDCCH1A

The DS200LDCCH1A is a Drive Control LAN (Local Area Network) Communications Board developed by General Electric for their Mark V series of drive and exciter boards. It is compatible with drives in the DIRECTO-MATIC 2000 Mark V Series subseries.

Functions provided by the board include operator interface, LAN communications, drive and motor processing, and drive resets.

The DS200LDCCH1A has instructional manual materials that are available online.

The DS200LDCCH1A is a revised version; the original product for this functionality was the DS200LDCCH1 parent board, lacking the DS200LDCCH1A's A-rated functional product revision.

Hardware Tips and Specifications

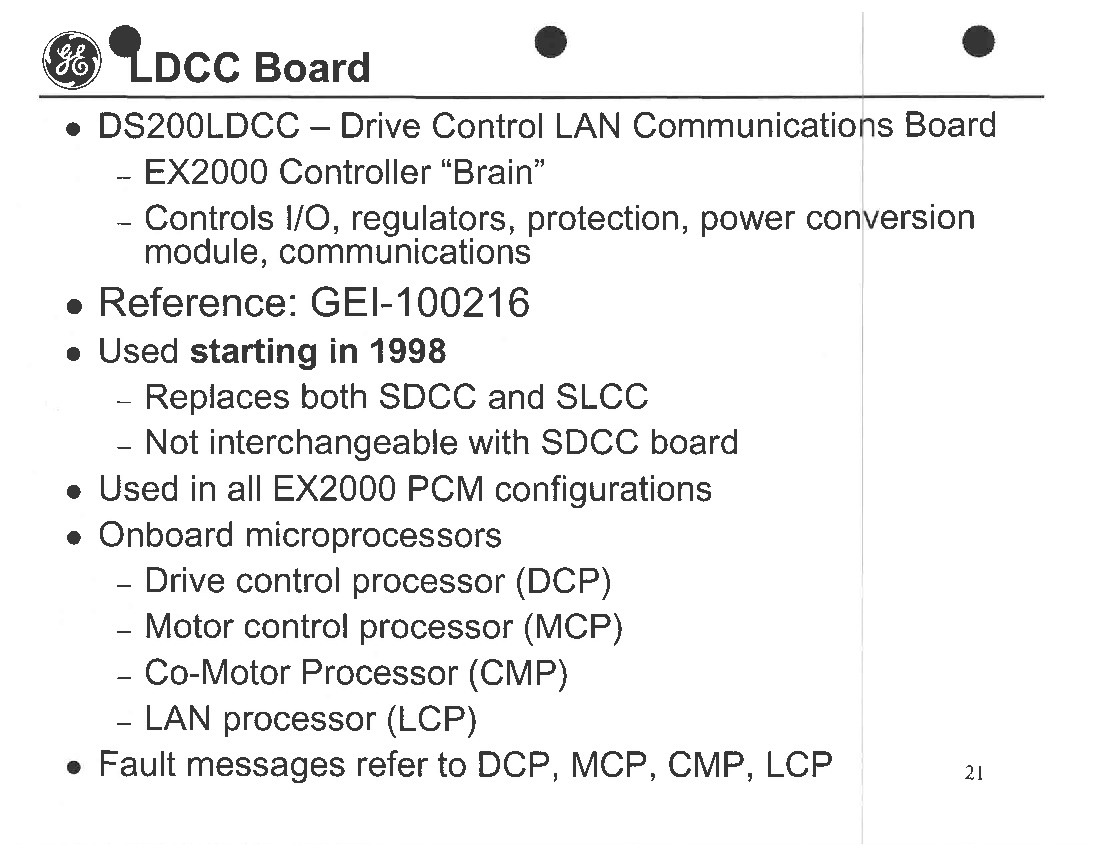

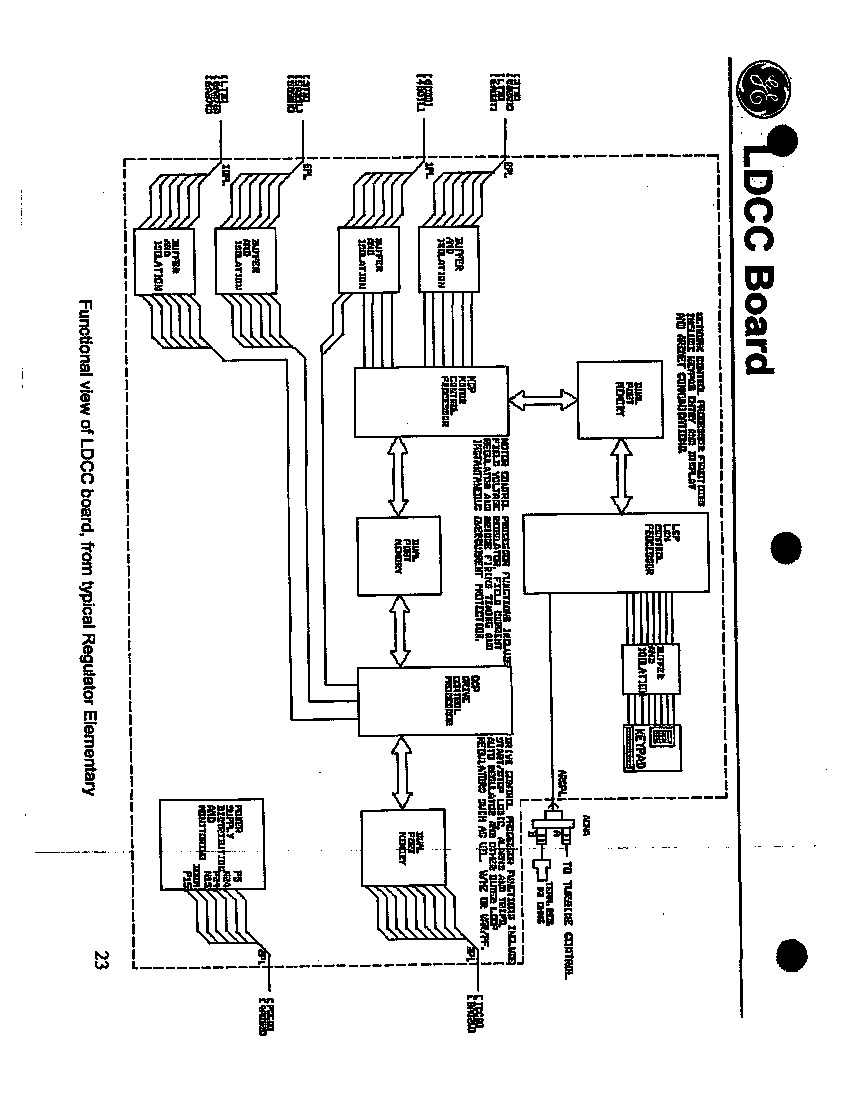

The DS200LDCCH1A communications card includes four microprocessors:

- LAN Control Processor (LCP): Accepts five bus systems.

- Drive Control Processor (DCP): Controls integrated peripheral I/Os (timers, decoders).

- Motor Control Processor (MCP): Controls motor control circuits and I/O communications.

- Co-Motor Processor (CMP): Provides additional processing power for complex math when the MCP's power is insufficient.

An alphanumeric keyboard is attached for user access to system settings and diagnostics.

It is one of the more commonly-manufactured products in the Mark V Series, featuring a standardized A-rated functional product revision.

The functional product acronym (LDCC) and naming components detail its normal Mark V Series assembly, domestic manufacture, conformal PCB coating style, and group one Mark V Series product grouping.

The board is shipped in a protective, static-reducing plastic covering.

Installation parameters, a comprehensive wiring guide, and technical support information are available in the series manual and device datasheet.

The A-rated functional product revision likely altered its original dimensions and performance specifications.

Supported Applications

- Microprocessor control and processing functions for drive, motor, and customer I/O.

- Microprocessor control of LAN drive I/O communications.

- Application software and customer-specific drive configuration data.

- Software adjustments and diagnostic testing via the onboard operator interface.

- Hardware and software reset drive functions.