About the DS200CDBAG1BBB

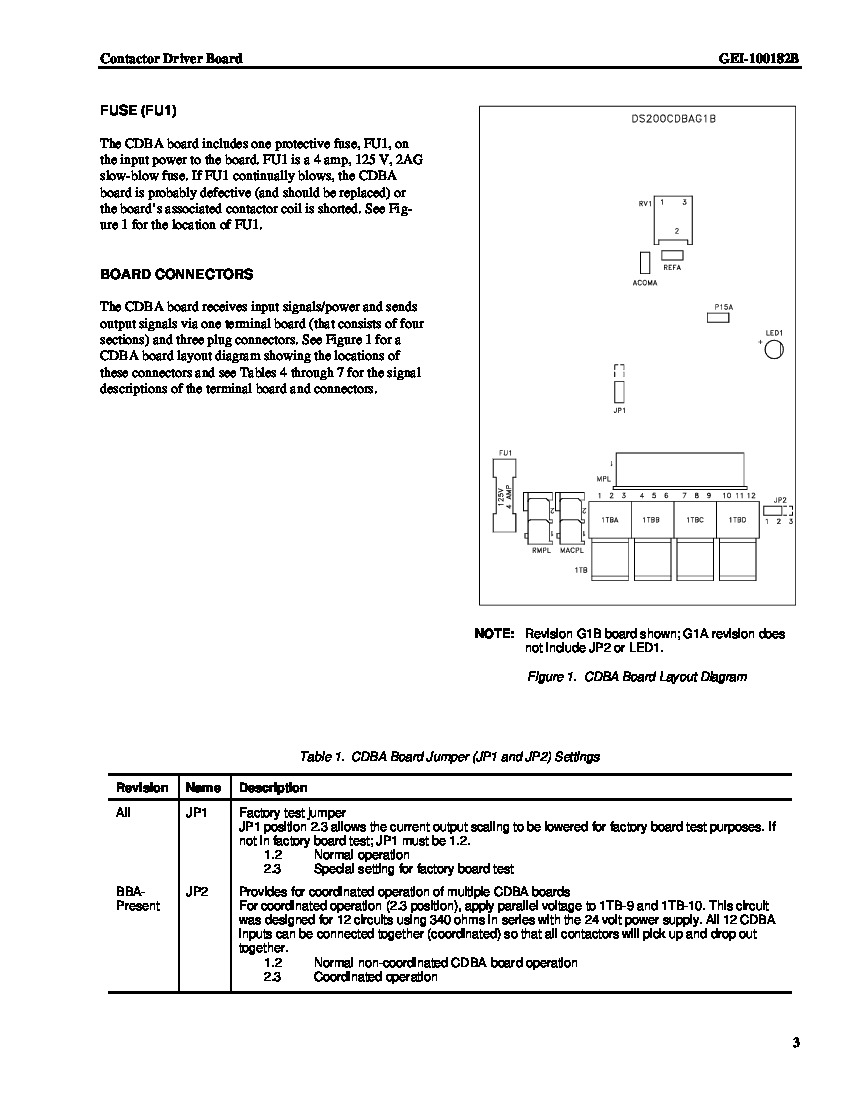

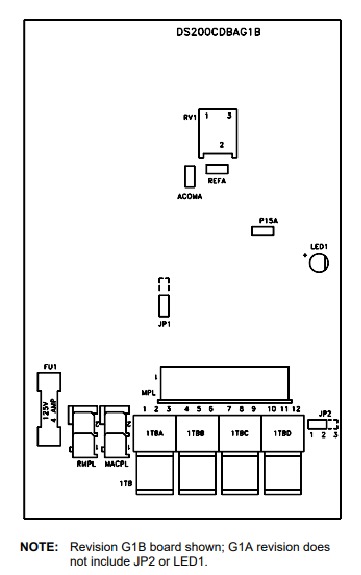

The GE Contactor Driver Board DS200CDBAG1BBB was created for its Mark V Series with the specific application of opening and closing a single contactor. All power, input signals, and output signals are connected to the DS200CDBAG1BBB board through 1 connector on the board (1TB). The 1TB connector is made up of four sections, those four sections being labelled as 1TBA, 1TBB, 1TBC, and 1TBD. Three total plug connectors supply the power and signals to the connector. To remove the connector, use a screwdriver to help pry the connectors apart from the board. Before you remove any cables or connectors of any type from the assembly of this DS200CDBAG1BBB Contactor Drive inherent to the assembly of this DS200CDBAG1BBB Board, it is considered best practice to label all cables to avoid confusion when you install the replacement board.

Additionally, one fuse connector is located on the board. If replacement is necessary use a 4 amp 125V, 2 AG slow-blow fuse. If the fuse blows often, you might suspect that the board needs to be replaced. It might be necessary to troubleshoot the board if you suspect the board is not functioning properly. Test points are on board for you test various functions of the board. You’ll need to use isolated test equipment to test the board. One point is the common reference point. The second test point is used for the 15 V dc power supply reference. The third is for the contactor driver reference.

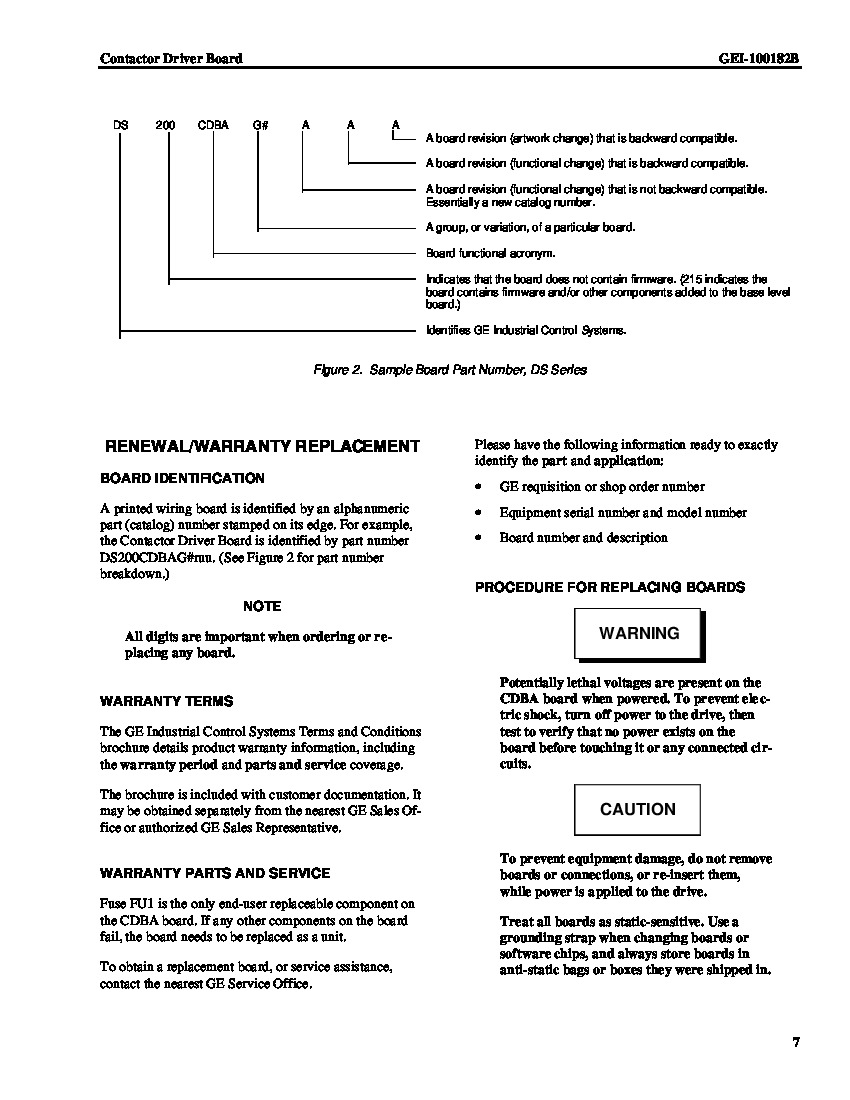

If you call to request service or customer support, be ready to identify the device by the part number before you call. The part number or catalog number is visible on the edge of the board. This DS200CDBAG1BBB part number is considered a functional product number, as it was developed specifically by General Electric to exist as a representation of its product's functionality. Several important hardware traits specific to this GE Contactor Driver Board are mentioned in its DS200CDBAG1BBB functional product number including its:

- normal assembly type

- CDBA functional acronym

- domestic location of manufacture

- normal PCB coating style

- group one Mark V Series grouping

- three B-rated significant product revisions

Please know the identifying information specific to this GE product before you call for service or assistance.