About the 9905-985

Model 9905-985 is a De-Energize-to-Trip model produced by Woodward for the ProTech 203 Overspeed Protection models. It has three 120 Vac/dc power supplies, one for each of the three speed-sensing units. There are two voltage ranges associated with this model due to the 120 Vac/dc power supply. The two voltage ranges are 88-132 for Vac and 90-150 for Vdc. The wattage associated with the 9905-985 model is approximately 7.25 W.

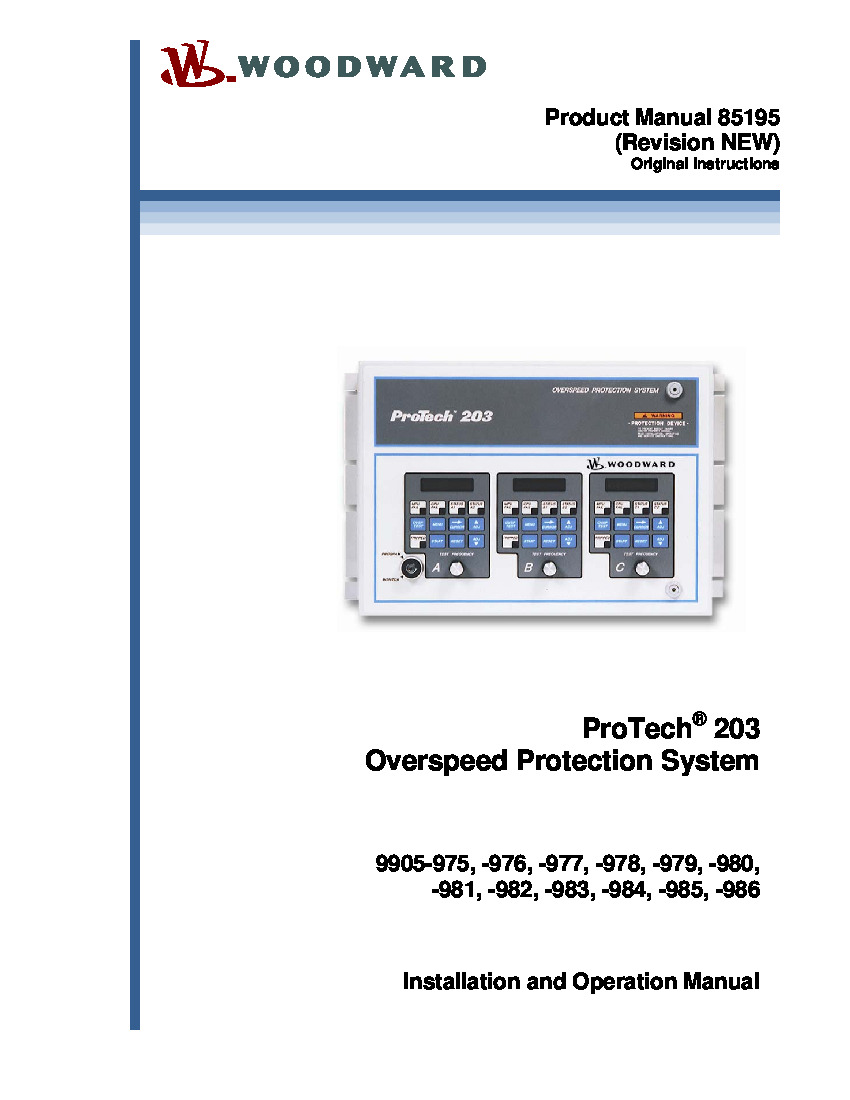

Along with individual power supplies, each of these speed-sensing units also has its operator interface. Units A, B, and C are identical, though they are programmed individually (identical programming is necessary for the correct and safe operation of this system). The units are programmed using the two-line LCD and touchpad on its corresponding interface.

To switch between MONITOR and PROGRAM modes on the 9905-985 unit, users must use a key to unlock the enclosure. When the optional stainless steel hubs are used, this enclosure is NEMA 4X certified. Tunable parameters and programming instructions are thoroughly outlined in Woodward’s ProTech 203 manual 85195. This manual also has information on features of model 9905-985, such as hot replacement, the built-in self-test, remote reset, and available functional status indicators and alarm outputs.

Manual 85195 also contains basic location considerations that must be taken into account before installing the ProTech 203 9905-985 model. This overspeed protection device is sensitive to many factors, like vibration, heat, and moisture, and a proper location is necessary to ensure the safe and accurate operation of this device.