About the 750-P5-G5-S1-HI-A20-R

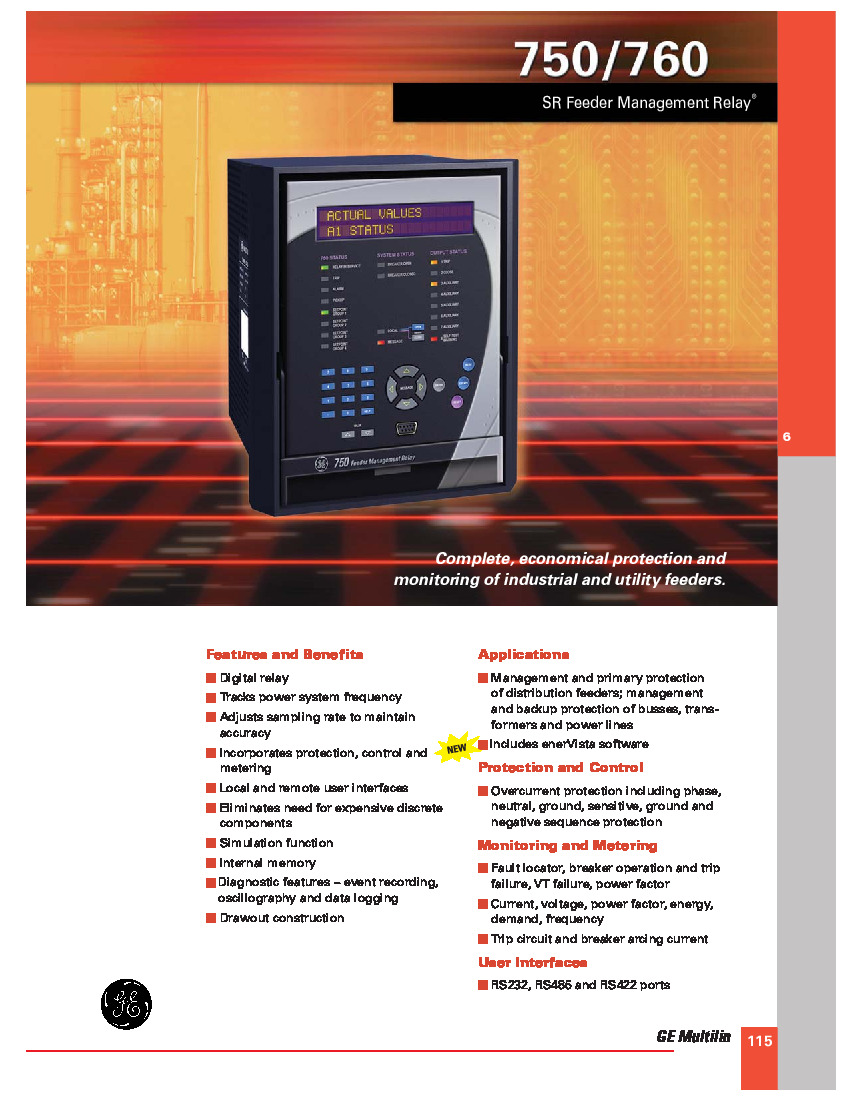

Able to be mounted on a standard 19-inch panel alone or alongside other 750 units, the 750-P5-G5-S1-HI-A20-R Feeder Management Relay is an excellent choice for distribution feeder control and protection needs. Features such as time overcurrent protection and frequency protection extend distribution feeder life by shielding system components in the event that issues arise within the system. Other features like oscillography or data logging diverge from being primarily protective and instead offer insights into system efficiency and where issues begin. Users can view, trend, graph, and export this data for further analysis and subsequently make efforts to improve the system.

The 750-P5-G5-S1-HI-A20-R features multiple communications ports, including the RS232 port on the front of the relay and the RS422/RS485 ports on the back of the case. The RS232 port is most suitable for direct connection to a computer running GE Multilin’s EnerVista 750 software, while the RS422/RS485 ports are more optimal for users seeking to monitor multiple relays at one time. The EnerVista 750’s Plug & Play feature makes configuring the software program straightforward and quick. Within the program, users can create, remove, and edit system settings to adjust how processes unfold within the relay. Additionally, users can view system data collected through metering, data logging, and waveform capture functions. This data can be plotted using features inherent to the EnerVista 750 software program.

These aforementioned user-configurable settings, referred to as “setpoints” in GE Multilin’s 1601-0120-AE manual, have enormous bearing on how protective features unfold during normal relay operations. For example, trips are only initiated after system values exceed both a user-set value for a user-set amount of time. This means that protective processes are highly dependent on user configuration. As a result, users should ensure that an experienced technician handles setpoint configuration and modification over time.