What is a PCB?

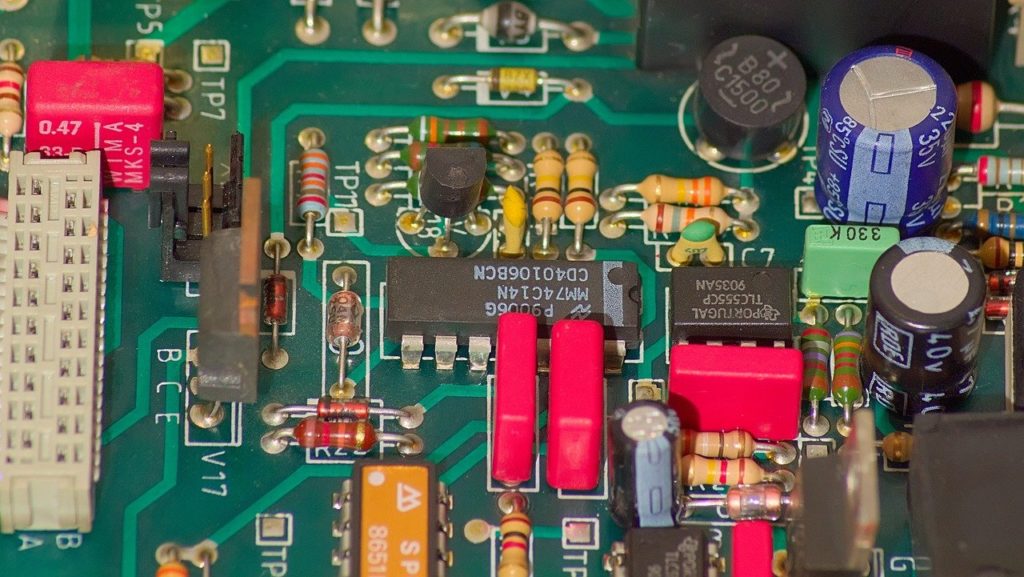

A PCB, or printed circuit board, is one of the most fundamental components in electronics today. They are used in everything from everyday items like cell phones, computers, appliances, vehicles, and musical equipment to jets and nuclear power plants. PCBs allow electricity to travel between components across pathways etched into the surface of the board rather than use wires, allowing a significant simplification and reduction and size. Printed circuit boards have become so commonplace even the cheapest electronics now often have some sort of board component.

Continue reading “Printed Circuit Board Basics”

You must be logged in to post a comment.