At AX Control we do a lot of repairs on motors and drives. Not only do we offer repair services for our customers, but we also examine every reconditioned part leaving our warehouse for defects and optimize its performance before it gets boxed up for transit. Our people get plenty of hands-on time with all sorts of drives and motors.

Skilled technicians take care of all our repair work. We back up that work with a 2-year warranty for AC/DC and Servo Drives, and a one-year warranty for Motors.

But do you know what may lead to your components needing repair? We get there’s a lot to know about industrial automation equipment. We thought we would offer up a list of the most common causes we’ve noticed, partitioned by type of drive or motor.

AC Drives

There have been many technological advances in the field of AC Drives that have brought more features to these drives even as they’ve decreased in size and cost.

The primary driver of repairs in AC Drives, without a doubt, is heat. This may come from various sources, but when you get to the root of the problem heat is the cause of the damage.

Here are a few of the most common ways heat strikes:

- A dusty environment. When fans aren’t cleaned on a regular basis, the drive can’t pull air through, and heat builds up. Protection is easy: maintain a regular maintenance schedule and keep fans and other heat dissipating equipment clean. Try to cut down on the amount of dust in your environment through mitigation.

- Power spikes. These can come from other machines, from lightning strikes, or from your main power line. You can often limit these problems by adding a line reactor in front of your drive system to protect from transients and power surges.

- Too much power draw. If a drive is attached to a poorly-maintained motor, such as one with ungreased bearings, too much bearing wear, or shaft imbalance, this can cause a mechanical overload that increases the motor’s demand on the drive. Connected systems have to be maintained together or they will die together.

Age can also play a part in determining when an AC Drive requires repair. It’s natural for things to move toward disorder; even the second law of thermodynamics says entropy always increases with time. Luckily, industrial parts are designed to last, and AC Drives typically have a decades-long mean time to failure rate. But drives are rather like older cars: preventive maintenance done before a problem occurs can be significantly less expensive and have a better return than repairs done after a problem has presented itself.

DC Drives

The primary function of a DC drive is DC motor speed control. The rate of speed within the motor is proportional to the armature voltage and is inversely proportional to the field current.

DC Drives are typically Analog or Digital, with digital offering more parameter variations, and thus more options overall.

Repairs to DC Drives have the same root causes as AC Drives: most repairs are driven by heat and age. Direct current drives can be especially prone to damage at the point of entry for communication from a connected PLC, which may allow transients to damage the port or internal drive components. Additionally, DC Drives may need repair because of an internal short to ground in a connected motor.

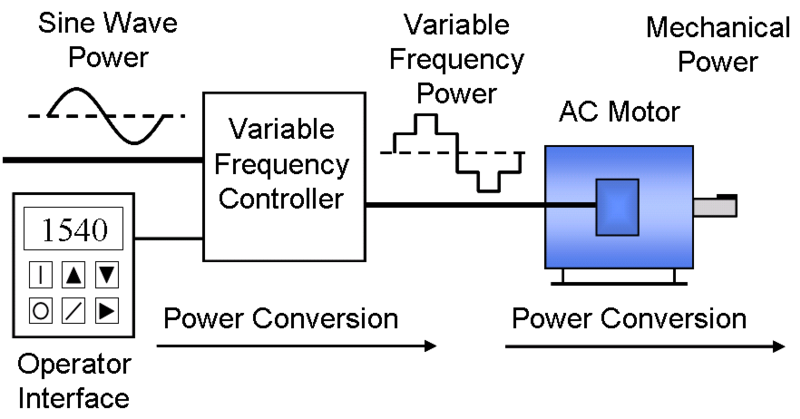

Variable Frequency Drives

VFD drives take incoming fixed AC voltages and internally convert them to variable VAC outputs. They’re capable of translating voltage and frequency to another V/F in order to vary motor speed without a loss of torque. These drives come in three main types:

- variable torque, often used in pumps, blower systems, and centrifugal fans

- constant torque, typically used for positive displacement applications or conveyor systems

- constant power systems, used for traction applications and power tools.

Like other drives, VFD drives are susceptible to heat damage. Cooling fan failure is a primary issue resulting in increased heat and thus, damage. Make sure to inspect and clean cooling components on a regular basis. But other problems can occur, too, such as

- Moisture infiltration in motors or drives. This can result in corrosive damage to internal circuitry. If your plant is damp, you may want to consider adding dehumidifiers. Additionally, sudden changes in temperature can also cause condensation to occur, so try to avoid sudden temperature changes.

- Loose connections in motors or drives. These can cause arcing and overcurrent faults. Correcting this sort of issue requires more than tightening down all screw connections. If you’re having a problem with arcing, it may be time for a complete inspection of your drive by a qualified technician.

Servo Motors & Drives

Servo systems use a motor, a controller, a feedback unit, and a drive. These systems provide precise control adjusting for linear and angular position, velocity, torque, and acceleration. Servos are very small, showing up in everything from RC aircraft to robotics, as well as woodworking, printing, and conveyor belts.

Servos are also prone to overheating, especially when the system must run for extended periods of time. Servo motors require a clean environment and proper airflow. Bearings sometimes go bad, or the motor axis may bind.

DC Motors

DC Motors are the workhorses of industrial automation. But it’s important to give them proper maintenance to maintain their lifespan. Some of the most common issues we see with DC motors are:

- Maintenance of Brushes and Commutators not given proper attention. Check brushes for wear or chipping, and check the drive to make sure there’s adequate spring tension. This keeps brushes against the commutator and properly aligned. Grooves or scratches on the commutator indicate brush sparking. Rough or blackened spots suggest the same. The resulting carbon dust/debris can excessively damage the commutator if left for too long.

- Bearings not properly lubricated. Some bearings in low horsepower motors never require lubrication. But for many motors, your lubrication schedule is critical. If your motor is hot to the touch or thumps or grinds when running, it may be beyond lubrication and into bearing failure. Check for worn bearings or rough races to determine your course of action.

- Failed field winding. This can also show up as brush sparking.

If you need help with any of these repairs, talk to the experts here at AX Control. We can help you with servo motor repairs, Variable Frequency Drive repairs, AC drive repairs, DC drive repairs, and DC motor repairs.

We’re also capable of helping you with a number of other industrial automation repair services. Check our repair page for more details and a complete list of the products we service.

Looking to purchase motors and drives? We can help with that too.

You must be logged in to post a comment.