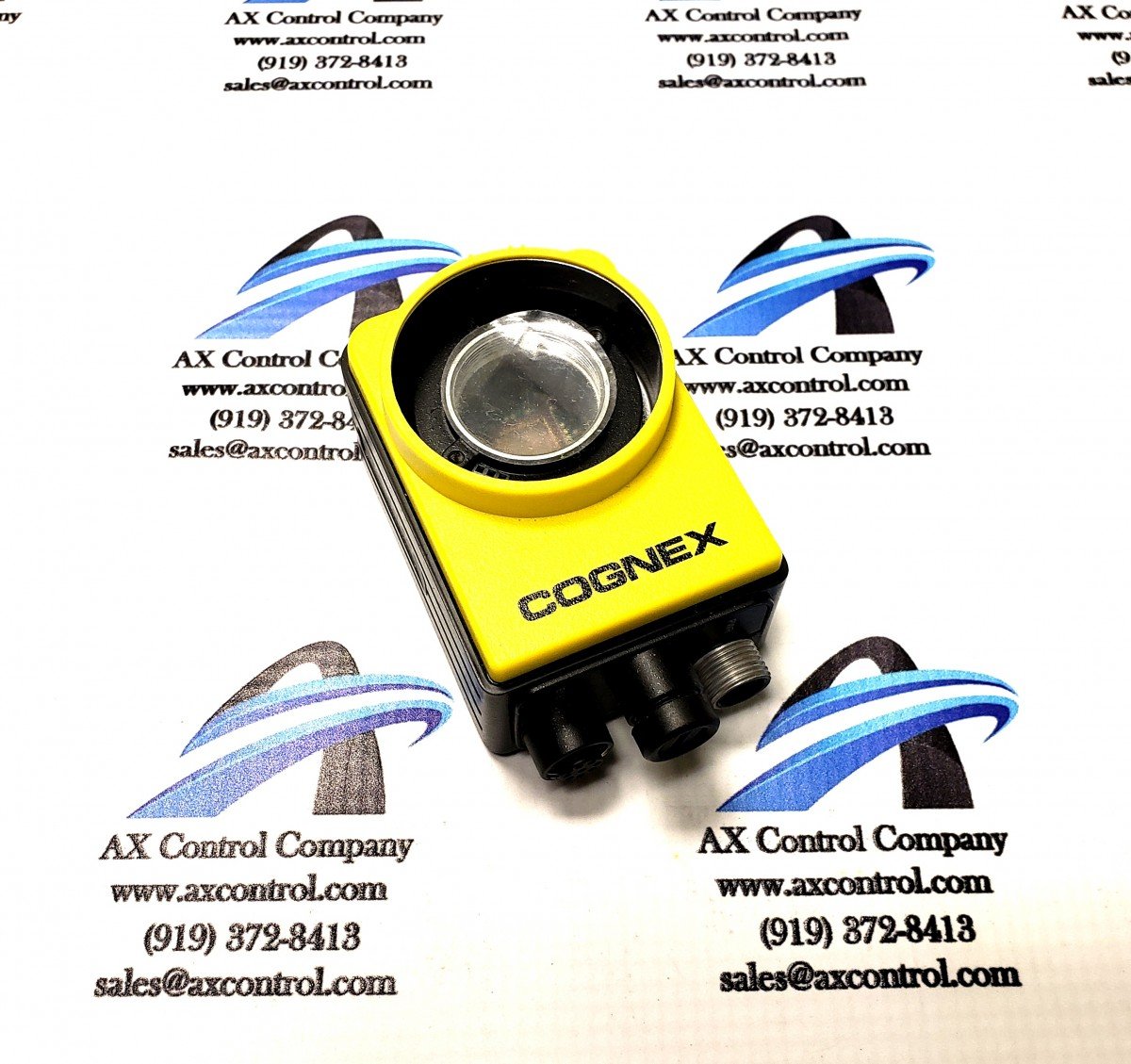

Why consider Insight 2000 Cognex or the Insight 8000 Cognex camera?

As sophisticated technologies are introduced into the manufacturing landscape, those who want to include robotics as part of their production line are looking for ways to increase the machine’s functionality, flexibility, and efficiency. This often means manufacturers are adding machine vision capability to their robotics to meet these goals. Cognex cameras are ideally designed for use as vision sensors.

How machine vision works

For most of their existence, robotics have used sensors, PLCs, and coding to create their movements. But despite what we may have inferred from pop culture references in movies like Terminator or from cartoons, older robots have difficulty picking up and moving small parts, especially parts lacking similarities on all sides, like a screw with a tapering shank connected to a rounded head….or Princess Twilight Sparkle parts.

Machine vision vision uses cameras as their sensors. These are connected to software algorithms that allow the robotics hardware to automate complex tasks or precisely handle equipment.

This process uses up to four cameras to transmit information back to the interface. With this information, algorithms can decide how and when to move hardware, and robotics can have up to a 360-degree view of their surroundings as they move through the manufacturing process.

Even when only one camera is utilized–which allows scanning of a single X/Y plane–machine vision can be used to recognize variations or anomalies in parts. But the recognition of variations and anomalies is part of how deep learning algorithms work within machine learning.

Robotics in Manufacturing

With recent improvements in both robotics, their associated software, and machine vision, robotics have worked their way into many facets of the manufacturing world. Robotics are now utilized in jobs like:

- Welding

- Shipping

- Product packing and palletizing

- Assembly

- Metal Fabrication

Robotics are improving the overall efficiency of manufacturing, and much of this is due to the improvements in how these machines see the world around them. This advancement in machine vision is being driven, in part, by the enhanced capabilities of vision technology. Many cameras, like some of our newer Cognex camera stock, like the InSight 8000 series offer higher resolution (up to 2592 x 1944) or faster acquisition rates (up to 217 fps) that make them ideal for use in machine vision. However, earlier versions like the Insight 2000 Cognex can be an affordable option. The Insight 2000 Cognex offers 1280 x 960 resolution and an acquisition speed of 40 frames per second.

How to choose a vision camera

There are several factors to take into consideration if you’re looking to select a camera to use for machine vision. Your budget will be the first factor. You also have to make sure to choose a camera designed for use in industrial applications where the environment may be hotter, dirtier, and tougher. Make sure to review vibration limitations. Also consider

- Resolution requirements. Know what you’re scanning for. Higher resolution cameras can pick up more detail. But does your application require pinpoint detail or will something less do the job?

- Imaging rate. How quickly will your camera have to acquire new information to do your job properly?

- Interconnection standards. How will your camera connect with your host computer? Some options include Camera Link, Camera Link HS, USB3 Vision, and GigE Vision.

- Type of scan required. Will you need an area scan or a line scan?

- Light wavelength. Some applications may require sensitivity to UV or infrared.

As this kind of technology continues to develop, material handling via robotics will become more commonplace. Three-dimensional vision technology will allow the system to completely understand the orientation and shape of raw parts, which can then be placed into assembly with precision, and will create a faster, more accurate throughput.

If you need a Cognex Camera or have more questions, contact our team today.

Want to know more about Cognex InSight? Read our answers to FAQs about Cognex here.

You must be logged in to post a comment.