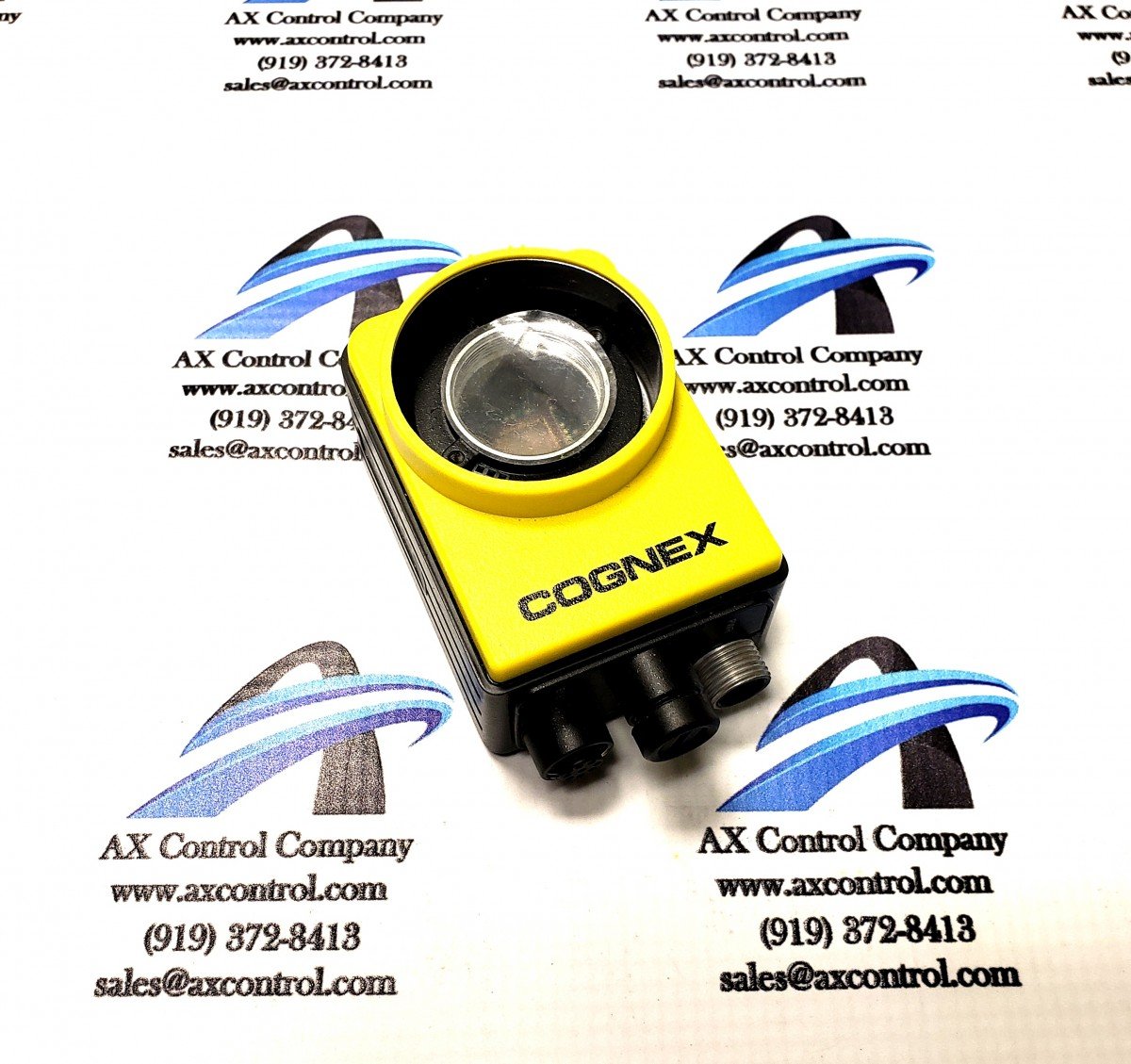

Why consider Insight 2000 Cognex or the Insight 8000 Cognex camera?

As sophisticated technologies are introduced into the manufacturing landscape, those who want to include robotics as part of their production line are looking for ways to increase the machine’s functionality, flexibility, and efficiency. This often means manufacturers are adding machine vision capability to their robotics to meet these goals. Cognex cameras are ideally designed for use as vision sensors.

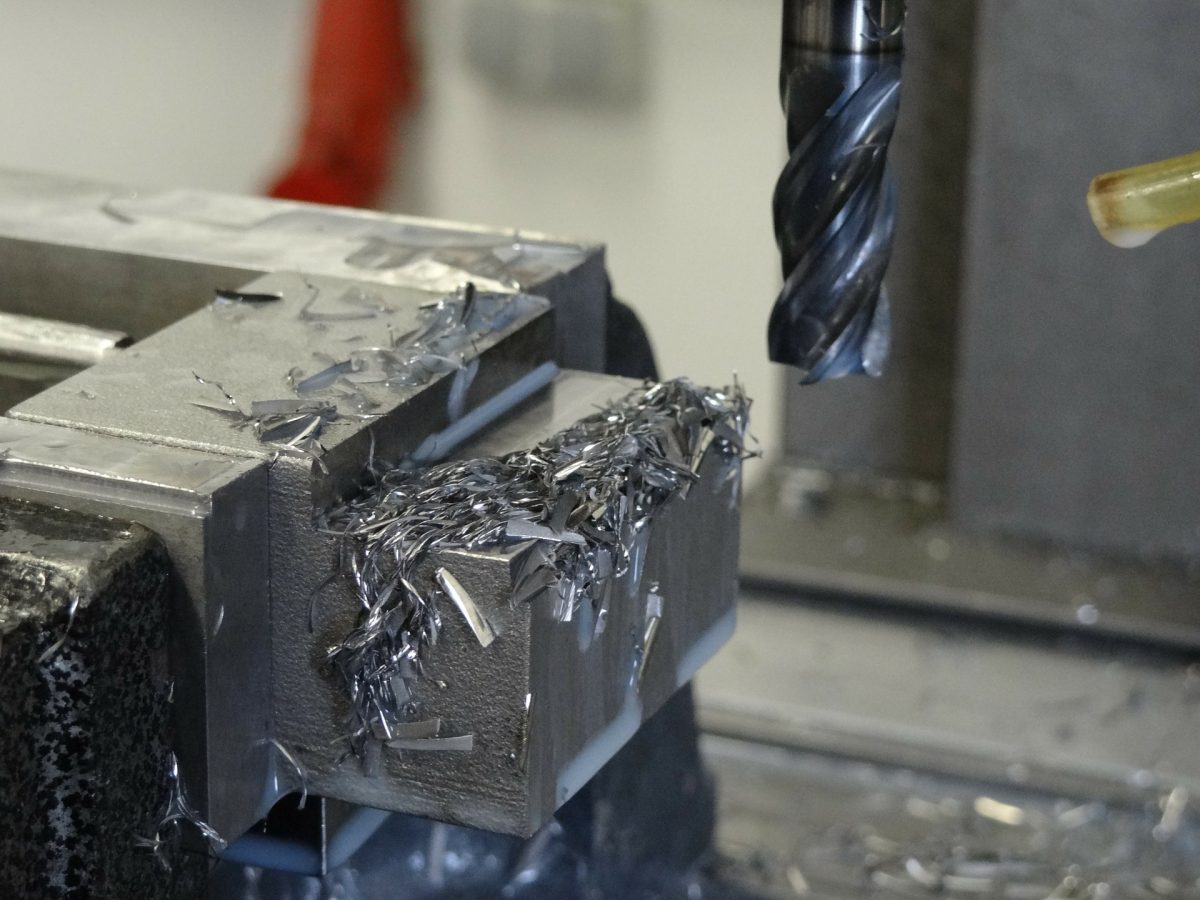

How machine vision works

For most of their existence, robotics have used sensors, PLCs, and coding to create their movements. But despite what we may have inferred from pop culture references in movies like Terminator or from cartoons, older robots have difficulty picking up and moving small parts, especially parts lacking similarities on all sides, like a screw with a tapering shank connected to a rounded head….or Princess Twilight Sparkle parts.

Continue reading “Machine Vision is Improving Manufacturing Robotics”

You must be logged in to post a comment.