AX Control is one of the largest resellers of motors and controllers in Raleigh, NC and beyond. We see a lot of different parts, and do a lot of repairs. After nearly a decade in business, we know a lot about them. So we thought it was time for us to do one of our FAQs covering some of the most asked questions and issues surrounding motors and controls.

Examples of Industrial Motors and Controllers

We specialize in industrial motors and controls. The design of industrial motors makes them ideal parts of blowers, machine tools, turbines, movers, or compressors. Motors may offer rotary or linear force. Such devices play a large part in manufacturing control systems include SCADA systems and PLCs (programmable logic controllers.)

Types of Motors and Controllers

There are four basic types of motors and controllers. They include

Stepper Motors and Controllers

Stepper drives and stepper motor controllers modify input power by changing the current source (typically AC) to a pulsed or “stepped” current output. Manufacturing motion control systems often use these devices. They may control position, torque, or motor speed.

Stepper drives might appear described as step amplifiers or as pulse drives. “Motor indexers” is another name for stepper controllers.

Servo Motors and Controllers

Servo drives and servo motor controllers change the constant or AC input power source into a pulsed output. Servo devices have a varying frequency or pulse duration.

Manufacturing motion control applications often use servo devices, just as they do stepper devices. Robotics, machine tools, spindle drives, and many other pieces of equipment use servo motors.

The terms “servo drive” and “servomotor amplifier” are interchangeable.

AC Devices

AC Drives and AC Motor controllers modify input power by adjusting power frequency for output torque and speed regulation.

These devices often factor into process applications. They offer speed control for pumps, blowers, fans, etc.

AC Drives are equivalent to variable speed drives, AC inverters, or adjustable frequency drives.

DC Devices

DC devices modify the input power (either constant or alternating current) into a pulsed DC output. This output has a varying frequency.

DC motors are made up of two distinct parts. One is called a stator. The other is called an armature.

The stator is stationary. It is built out of magnets and coils of wire. It provides the magnetic field that drives the armature.

Motors and Controllers: Industrial Applications

AC and DC motors are simple. They don’t need controllers or drives like servomotors or steppers, although they may require a motor starter. However, an AC motor drive may come into play when speed control is necessary. Motor drives increase efficiency by setting the speed to meet output requirements.

When speed doesn’t meet output requirements, issues with outputs can happen.

Brushed DC motors can offer speed control through voltage variation. A rheostat can accomplish this without the need for a controller. DC motors have good low-speed torque. Winches and cranes often use DC motors for this reason.

Main Parts of a Motor

While this may change slightly from type to type, motors generally have

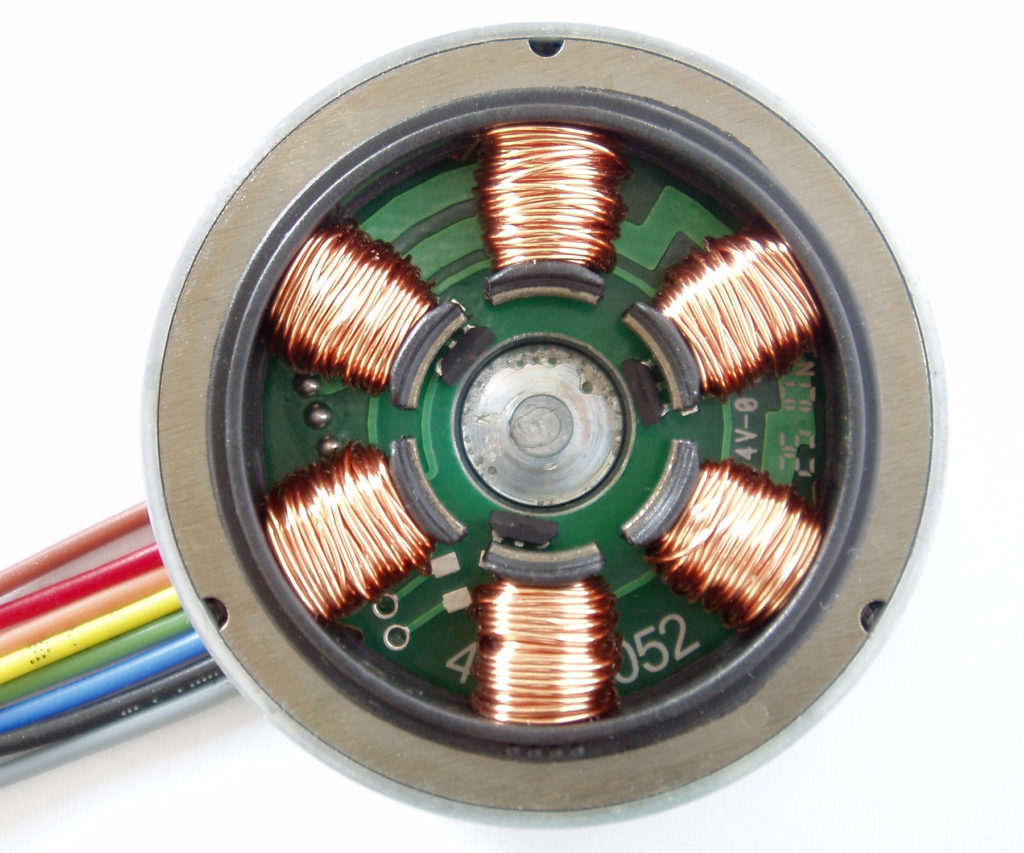

- A Rotor. The rotor is the moving (rotating) part of the motor.

- A Stator. The stator is the stationary part of the motor. This is where the windings live.

- Bearings. Bearings allow the rotor to turn on its axis. They literally “bear” the weight of the motor housing.

- Windings. The windings are wrappings of wires within the stator. They form magnetic poles when energized with the current.

- Air Gap. There is a literal air gap (a space of nothingness) between the rotor and the stator. It is very small. Large air gaps can negatively affect performance.

- Commutator. A mechanism that causes a current reversal to maintain motor rotation. Physical commutators appear in brushed DC motors. However, brushless motors use encoders or Hall effect sensors instead.

Do you have a drive or PLC that needs repair? We can help! Talk to the AX Control team today. We also sell drives, motors, and PLCs.

You must be logged in to post a comment.