Mechanical systems offer many different control options. One of these is the oddly-named bang-bang control. This short blog post answers some common questions about this control theory.

What is bang-bang control theory?

Bang-bang control is a kind of feedback controller, meaning it has a type of cause-and-effect closed loop. Bang bang controllers switch quickly between two different states, for example, completely on or completely off.

Examples of bang bang control

You’ve probably used bang bang control systems all your life without realizing it. This kind of control offers an “on” state and an “off” state with no variable between these. Thermostats–at least older versions–typically use bang bang control.

When the temperature rises above the setpoint, bang! the system clicks on and cooling begins. Cool air continues at full-out distribution until the thermostat’s temperature reading dips below the setpoint. Then bang! again, cooling stops. This is how the system developed its name.

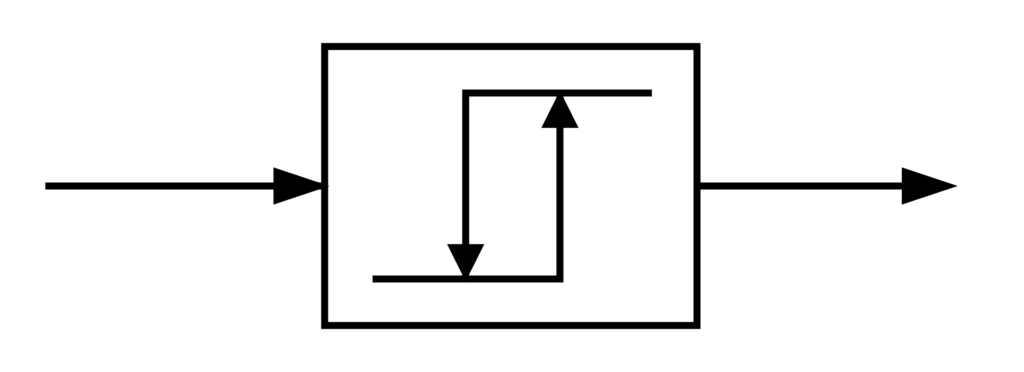

Here’s what bang bang control looks like in ladder logic PLC programming.

Bang bang control vs. PID

As we just explained, bang bang control offers no variables except “on” or “off”. Using the same example as above, when a cooling system using bang bang control attempts to cool an area, it will use the same amount of cooling resources whether it must change the temperature two degrees or ten degrees.

PID (Proportional, Integral, Derivative) control works differently. Unlike bang bang control, PID can offer varying levels of feedback to change how the system responds. PID control will recognize how much deviation there is between the current and optimal (target) point and will provide more response the further the system deviates from that target.

In other words, a cooling system with PID control will push more cool air out to deal with a ten-degree difference in temperature than it will a one-degree difference in temperature.

Need more information about industrial control systems like the Reliance Automax PLC line? We can help! Talk to our team today.

You must be logged in to post a comment.