When your electric motor fails, it can be difficult to know why. But there are quick tests you can use to easily diagnose problems.

Make sure to disconnect power from your electric motor before beginning. Power is not required. This step protects you and the equipment.

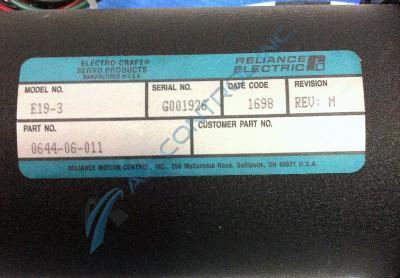

Motor Identification

Electric motors have a metal nameplate or tag riveted to the outside of the motor housing. This nameplate usually includes a lot of useful information, including

- Manufacturer Name. Who made the motor.

- Serial Number or Model Number. The model number tells you the make of your motor. The serial number uniquely identifies it.

- RPM. Revolutions Per Minute. The output capability of your motor.

- Horsepower. A rating of motor performance.

- Voltage. The motor’s voltage requirements.

- Current. How many amps the motor requires.

- Frame Style. The unit’s physical dimensions.

- Type. This can include NEMA ratings, cooling indications, etc.

A wiring diagram may also be included on the nameplate. In some cases, this tag will include the unit’s manual identification number, too.

Visual: Check the Outside of the Motor

You can spot some issues right away using a quick visual inspection. Some problems that can shorten a motor’s life include

- Broken feet or broken mounting holes. This is called having a “soft foot.” Soft foot failures increase play in the machine as it runs. This, in turn, can result in shaft wear, bearing failure, and winding failure caused by excessive vibration and excessive heat.

- Darkened external paint. If this is near the middle of the motor, it may indicate excessive heat build-up.

- Dirt. If dirt makes it through housing openings, it can cause issues to motor windings.

Physical: Bearing Check

Once you’ve completed a visual check, it’s time to check the bearings. This test is done using your senses of touch and hearing.

Put the motor on a flat, solid surface. Then hold the top of the motor with one hand and spin the shaft/rotor with your other. The rotor should spin freely and quietly. If you feel or hear scraping or rubbing, your bearings may be worn. Also, try to notice if the shaft wobbles off-center as you rotate it. Rotations should be even.

Next, try to move the shaft in and out of the frame. Most motors have a little play. But more than 1/8th of an inch may indicate bearing problems.

Tool required: Check the Windings

The wires inside the motor coils are called windings. These create the magnetic force driving the motor. Sometimes these wires touch the frame around them and short circuit, causing motor issues. You can check this by using an ohmmeter.

- Check resistance value. We suggest looking at your operation manual for this test. Typically, the test uses the highest scale available on the meter. Touch the probes to each other to zero out the meter. Then find a motor ground screw. Attach one ohmmeter test probe here. The other probe will attach to each motor lead in turn. The meter should read a resistance value in megaohms. Lower resistances may indicate an issue.

- Check that windings are not blown or open. We suggest looking at your operation manual for a description of this test.

Other Possible Motor Problems

Look for leaking oil, holes, bulges, or a burnt smell. These may indicate a blown start capacitor. Use the ohmmeter to check it.

Also, make sure your switch contacts are clean and operating properly.

If your motor has a fan, make sure it is still fastened securely and that it isn’t clogged with dirt or debris. A dirty fan won’t properly cool your motor.

Finally, be sure you’ve used the correct motor for your application. Every motor has recommendations for use, including proper ambient temperatures, humidity levels, even altitude restrictions. If you’ve used the wrong motor, it’s sure to fail eventually.

If you need help with motor or drive repairs, AX Control can help. Talk to our team today.

*****

Did you know Feedspot recently named us as one of the world’s top Automation blogs?

You must be logged in to post a comment.