What do you know about circuit board reference designators?

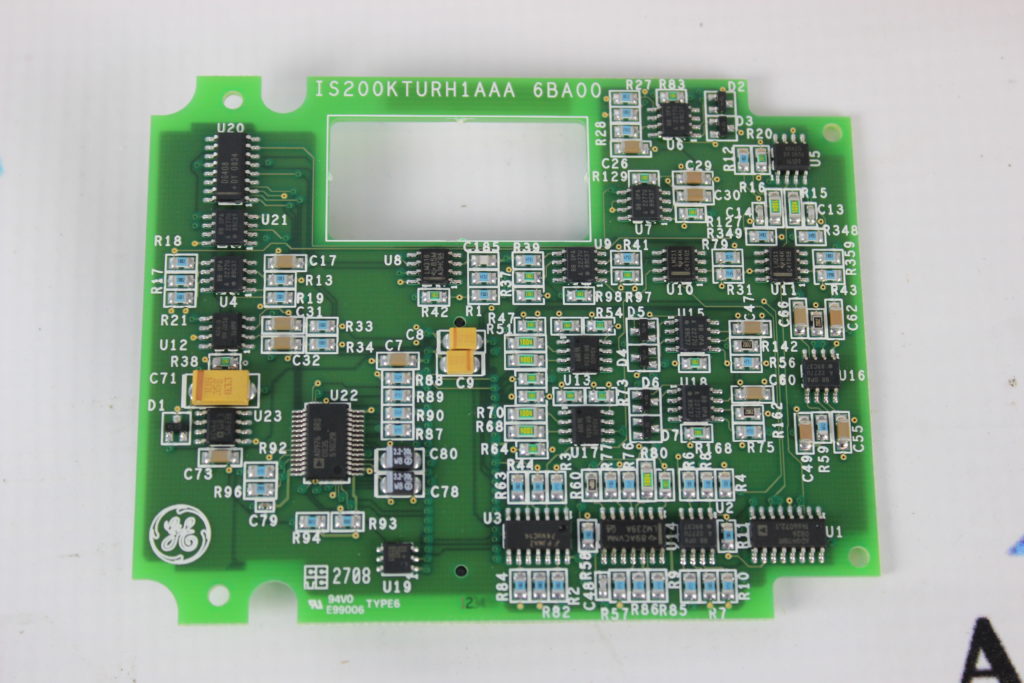

If you’ve worked with printed circuit boards (PCBs) at all, you’ve noticed the letter codes on their surface. These are called reference designators. If you’ve designed circuit boards, you’ve probably spent more time than you want thinking about them.

What are Reference Designators?

Circuit board letters can be confusing when you first start working with components. These small codes litter the board’s surface and are sometimes hard to read. And sometimes they don’t make sense. Q for transistor? U for integrated circuit? What the heck.

Reference designators identify components on a circuit board or within an electrical schematic. In most cases, one or two letters plus a number make up the reference designator. This standard grew from codes uses by the American military as early as the 1950s. From there, standards moved through the IEEE (Institute of Electrical & Electronics Engineers) to ASME (American Society of Mechanical Engineers), which provided the most recent guidance in its ASME Y14.44-2008.

However, depending on the age of the component you’re working on, earlier standards may apply. This means some designators may mean one thing on one circuit board and mean something entirely different on another.

Most Common Circuit Board Reference Designators

Here’s a list of the most common reference designators. We’ve notated some secondary options that are sometimes used instead.

| Designator | Component Type | Alternate |

| A | Separable Assembly | ASSY |

| BR | Bridge Rectifier | |

| BT | Battery | B |

| C | Capacitor | |

| CRT | Cathode Ray Tube | |

| D | Diode | LED |

| F | Fuse | |

| FB | Ferrite Bead | L |

| FL | Filter | |

| G | Generator, sometimes Oscillator | |

| H | Hardware | MP |

| H | Pin Header | |

| J | Jack | |

| JP | Jumper | J, JW |

| K | Relay. Contactor | RY, RLA |

| L | Inductor Coil | |

| LCD | Liquid Crystal Display | |

| LED | Light-emitting Diode | |

| MK | Microphone | MIC |

| MOSFET | Metal Oxide Semiconductor Field-effect transistor | See Q |

| MOV | Metal-Oxide Varistor | |

| NE | Neon Lamp | |

| OP | Opto-isolator | |

| P | Plug | |

| PCB | Printed Circuit Board | |

| PS | Power Supply | |

| PU | Pick Up | |

| Q | Transistor (all types) | FET, JFET, TFT MOSFET |

| R | Resistor | LDR, VDR, VR |

| RN | Resistor Network | |

| RT | Thermistor | TH |

| RV | Varistor Variable Resistor | VR |

| SCR | Silicon-controlled Rectifier | |

| S | Switch | SW, SUS |

| T | Transformer | VT |

| TC | Thermocouple | |

| TP | Test Point | |

| TUN | Tuner | |

| U | Integrated Circuit | IC |

| V | Vacuum Tube | |

| VR | Voltage Regulator | |

| W | Wire | |

| X | Socket connector Crystal | |

| XTAL | Crystal Oscillator | Y |

How to Use Reference Designators

Reference designators are important for several reasons. During the design and creation steps, they ensure assembly matches the design. They also help speed up the inspection process that typically occurs before PCBs leave the factory, allowing inspectors to quickly identify, match, and approve each component.

Later on, once the PCB has been delivered to the consumer, it helps the user understand and identify each part of their component. This can become especially important if some part of the PCB becomes damaged. Rather than calling the manufacturer with a non-specific “Something is messed up,” they instead can say “Our board seems to need a new F3 fuse. Is that user-replaceable or do I need to send it in for service?”

Finally, if you sell industrial surplus like AX Control, identifying and understanding components helps us ensure we only sell refurbished boards in good working order. And if you buy from companies like us, it can help you recognize the difference between a good surplus supplier and one that may not be as good.

Want to know more about how to identify circuit board components? We have an in-depth blog on that.

If you need to purchase GE circuit boards for turbine control, talk to our team today.

You must be logged in to post a comment.