One of the greatest challenges for any successful business is knowing when it’s time to change. After all, conventional wisdom says “if it’s not broke, don’t fix it.” But with 21st-century manufacturing technology changing at such a rapid pace, those who stand still will soon be left behind.

The last time the world saw technological advancements at this pace, Henry Ford was just figuring out the assembly line. By looking back at Ford’s adoption of the new technology of his time we may be able to learn how to properly read today’s technological trends. This knowledge will help prepare us for investing in AI and automation at the most advantageous time for our manufacturing, warehousing, and distribution systems.

Leverage Automation

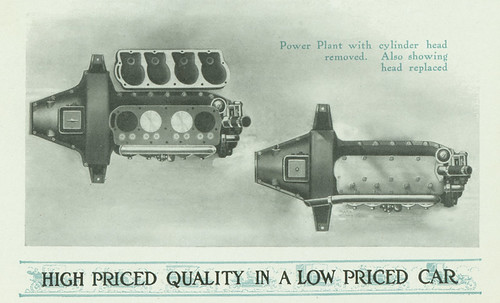

Henry Ford was not a newcomer to the car business when he began producing the Model T in 1908. Before starting the Ford Motor Company, Henry worked for several other automotive companies where he contributed to the creation of the Quadricycle and the Ford 999. But he dreamed of a vehicle for ‘the great multitude,’ and so the Model T was born.

Unfortunately, the original Model T was still too expensive for most Americans. When Ford began churning the cars out via assembly line, however, their price dropped significantly.

In 1909, workers were using traditional methods to piece cars together. That year, a Model T cost $825. Production was under 11,000 units. But in 1916, three years after Ford started using assembly line production, the Ford Motor Company produced over half a million Model Ts. Each one sold for $345.

Automation can lead you to consider opportunities in ways you haven’t before. A shift in production capabilities and costs allows you to reconsider your market from a new perspective. Higher productivity and efficiency equals a lower per-unit cost that will change how competitive you are within your market.

Put Your Workers First

Henry Ford significantly altered the lives of his workers. At the beginning of assembly-line production within the Ford Motor Co, most workers managed 9-hour days for about $12 a week. But the shift was awkward, the work was hard, and turnover was high.

So Ford changed the work periods to three 8-hour shifts and doubled the worker pay through a bonus structure. This, in turn, decreased his labor turnover and allowed for smooth, uninterrupted production of his cars.

Despite fears, current technology does not take away jobs. In fact, automation may help increase the number of skilled, high-paying jobs within the manufacturing sector since an automated shop has a need for better trained, higher-skilled workers.

This can be a win-win for an existing company and its current workforce. Offer educational reimbursement to employees who want to retrain to gain more expertise. Your employees gain 21st-century skills that allow them to remain with the company in a better-paid position. You retain good employees who have a proven track record of reliability.

Decrease Waste, Increase Efficiency

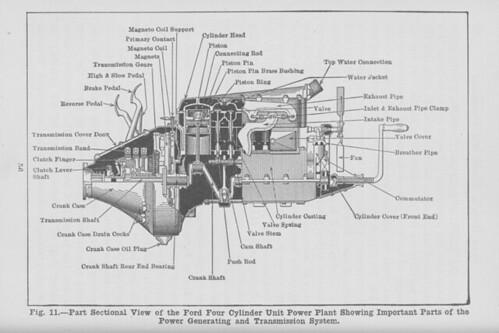

One of the primary advantages of Henry Ford’s assembly line was its increased efficiency. The Model T went through 84 individual assembly processes. Each process used interchangeable parts mass-produced elsewhere. The number of permutations this allowed is extraordinary and might have led to chaos. But workers trained to do one job each, making each particular job a simple step in the whole.

While this seems like common sense today, it was a revolutionary idea in 1913. Worker productivity increased to such a level that the time to put a single Model T together dropped from over 12 hours in 1908 to 93 minutes in 1914.

Automation can make the same kinds of leaps in efficiency for your company. When Factory Five Racing, Inc was looking to decrease the time it took to produce their hot rod trim kits, they turned to robotic automation. The change allowed them to produce a higher quality trim kit consisting of four sets of panels (four trunks, four hoods, and eight doors) in 24 minutes, down from 7.5 hours.

Increased efficiency tends to improve throughput, reduces environmental impact due to lower energy use, and cuts costs.

Be Flexible

Henry Ford famously said, “Any customer can have a car painted any color that he wants so long as it is black.” While this doesn’t imply a flexible business outlook, Ford’s assembly line was remarkable in its flexibility. At the height of Model T production, there were eleven different bodies built upon the basic Model T chassis. Customers could order a racer, a snowmobile, a police wagon, or a woody wagon. Customers could order thousands of accessories to round out their purchase.

Flexible automation allows your plant to switch over to take on new processes without a full retrofit. Think ahead about what challenges might occur down the road and try to prepare for them during the initial design phase. For example, choosing robots with an open interface will allow for the later connection of third-party equipment for customized processes. This is where working with an experienced robotics/AI design firm can pay significant dividends later.

Some say “The more things change, the more they stay the same.” While Henry Ford’s assembly line and basic business practices have long been replaced by modern lean manufacturing and Industry 4.0, we can still apply Ford’s reasons for improving processes to today’s changing industrial landscape.

Looking for replacement industrial automation parts? We can help.

Manufacturingtomorrow.com originally published this article on October 7, 2019.

You must be logged in to post a comment.